EV drivers can save as much as $14,500 on fuel costs over 15 years compared to driving a legacy vehicle. That’s the conclusion of a new analysis conducted by researchers at the DOE’s National Renewable Energy Laboratory (NREL) and Idaho National Laboratory (INL).

The new report, Levelized Cost of Charging Electric Vehicles in the United States, published in the journal Joule, examines the cost of EV charging in greater detail than previous studies. It provides a state-level assessment, taking into account the thousands of different retail electricity tariffs around the country, and considers when, where, and how a vehicle is charged. It also considers the real-world costs of charging equipment and installation.

“Finding out the purchase price of a vehicle is relatively simple, but the savings related to fuel aren’t readily available, especially since electricity cost varies greatly for different locations and charging options,” said co-author Matteo Muratori, a Senior Systems Engineer at NREL.

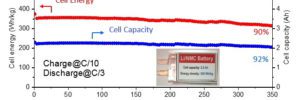

The cost to charge an EV varies widely. The key factors include differences in the price of electricity, the types of equipment used (slow or fast charging), the cost of installation, and vehicle use (miles driven). The researchers calculated that the national average cost to charge a battery EV ranges from 8 cents per kWh to 27 cents, with an average of 15 cents. This corresponds to an average lifetime fuel cost savings of $3,000 to $10,500.

However, in certain scenarios, the savings can be much lower or higher than the average. The researchers found that, in Washington state, an EV driver can save as much as $14,500. On the other hand, certain drivers in Alabama, Hawaii, Mississippi or Tennessee may fail to realize any savings compared to a legacy vehicle.

In calculating costs, the researchers also considered the nature of the charging stations. The average cost figure of 15 cents per kWh assumes 81% of charging is done at home, 14% at a workplace or public station, and 5% at a DC fast charger. Exclusively charging at DCFC stations increases the average cost to 18 cents per kWh, while charging exclusively at home brings it down to 11 cents. EV owners who can take advantage of time-of-use pricing can see costs as low as 8 cents per kWh.

Source: National Renewable Energy Laboratory

source https://chargedevs.com/newswire/new-study-ev-fuel-cost-savings-vary-widely-across-the-us/