Wednesday, 30 September 2020

SEMrush Free Trial 2020

from WordPress https://ift.tt/2GoO21M

https://ift.tt/2GoO21M https://ift.tt/30nAWZK

Mersen introduces Infini-Cell battery assembly solutions

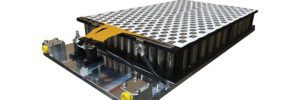

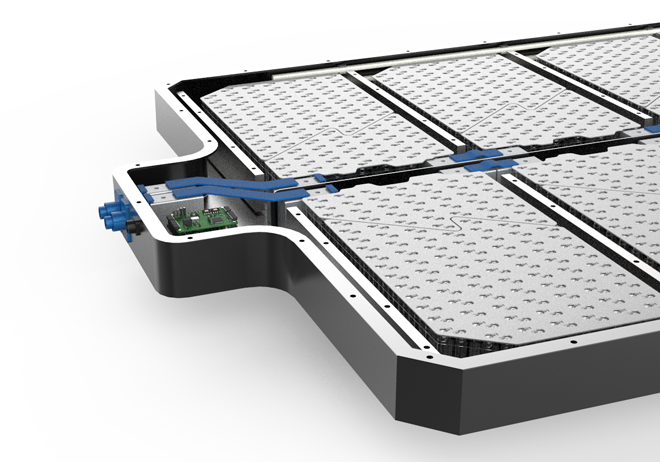

Mersen, a specialist in thermal management, overcurrent protection devices and laminated monitoring bus bars, and F & K DELVOTEC, a designer of laser bonding equipment and processes, have joined forces to create Infini-Cell, a new solution to support 21700 series battery assembly systems.

F & K DELVOTEC says its laser bonder interface guarantees a high-speed, safe, robust and efficient connection of the battery cells to the laminated bus bar, more than four times faster than conventional wire/ribbon insertion and welding. The laminated bus bar is an ultra-thin single layer with interleaved contacts. The “smart” bus bar not only powers the battery cells but also monitors temperature and voltage of battery cells as needed. To protect the battery assembly from over-currents, a special low-power-loss/high-cycling DC-rated fuse is installed. The battery assembly is then secured onto a compact (7 mm thick) liquid-cooled cold plate, providing homogeneous cooling to all battery cells.

Source: Mersen

source https://chargedevs.com/newswire/mersen-introduces-infini-cell-battery-assembly-solutions/

Lion Electric to deliver 10 electric trucks to Amazon

Amazon has ordered 10 battery electric trucks from Lion Electric, and the first two will be delivered this year. Amazon plans to use Lion’s trucks in its middle-mile trucking operations, transporting items within the company’s network.

Lion will provide a training session for Amazon’s drivers, and will also establish a maintenance program for the trucks. The trucks will be manufactured at Lion’s Canadian facility, which has a current capacity to produce 2,500 electric trucks per year. Lion is also planning to open a larger manufacturing facility in the US.

Quebec-based Lion Electric manufactures electric Class 5 to Class 8 commercial trucks, as well as buses and minibuses for the school, paratransit and mass transit segments. The company has delivered over 300 all-electric school buses in the US and Canada. Lion designs and builds all its vehicles’ components, including chassis, battery packs, truck cabins and bus bodies.

Marc Bedard, CEO and founder of Lion, said, “This vehicle delivery for Amazon represents a very significant milestone for Lion. Designing and manufacturing all-electric vehicles is a challenging and lengthy process. We’ve been at it for more than 10 years now; we know what works in practice, but also what only works on paper. We are in a unique position to disrupt the heavy-duty truck segment by offering an unmatched all-electric product, as we have already done in the school bus segment.”

Source: Lion Electric

source https://chargedevs.com/newswire/lion-electric-to-deliver-10-electric-trucks-to-amazon/

Dürr to partner with Techno Smart for battery electrode coatings

A pair of industrial coating specialists, Dürr and Techno Smart, have reached an agreement to provide technologies for coating lithium-ion battery electrodes.

Dürr CEO Ralf W. Dieter said, “With Techno Smart as our cooperation partner, we want to secure a larger share of this future-oriented market. The Japanese company’s coating systems are in high demand among battery manufacturers for electric cars. That is why Dürr is now bringing the coating specialist’s technology on board.”

Dürr Deputy CEO Dr. Jochen Weyrauch added, “This improves our marketing prospects, and provides us with a convincing all-round package for major projects in the automotive sector.”

Eventually, producers of EV batteries will receive complete packages from a single source at Dürr, including technology for coating and drying electrodes as well as solvent recovery systems.

With the acquisition of the US company Megtec/Universal in 2018, Dürr expanded its portfolio by adding competencies in battery manufacturing technology. With its coating, drying and solvent recovery systems, Dürr Megtec offers solutions for three essential steps in the production of lithium-ion batteries. Dürr Megtec is part of the Clean Technology Systems division.

In battery manufacturing technology, Dürr’s portfolio includes solutions for battery module coating and gluing technology and coolant filling systems. Dürr also provides painting, final assembly and testing systems for EVs.

Source: Dürr

source https://chargedevs.com/newswire/durr-to-partner-with-techno-smart-for-battery-electrode-coatings/

Solder redefined: Indium’s materials provide EV power electronics solutions

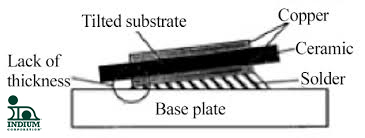

Vehicle manufacturers and materials suppliers are facing increasing packaging challenges as EV designs continue to push for higher power densities, while footprints remain static or become smaller. Higher performance levels mean higher junction temperatures, which in turn require higher thermal reliability and novel thermal management alternatives. These factors create unique reliability challenges for EV power modules, which can lead to common field failures, for example:

- Harsh environments cause thermal cycling and thermal shock defects.

- Mismatched CTE leads to component layers detaching from one another.

- Uneven bond line thickness between the substrate and baseplate increases stress concentration and reduces fatigue resistance during cycling.

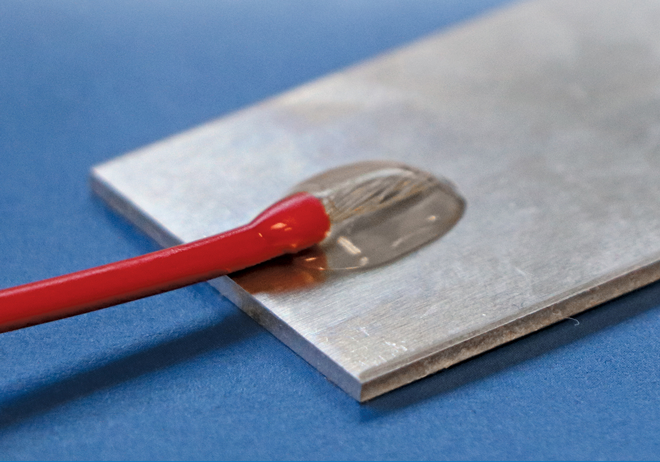

Indium, a designer and manufacturer of electronic assembly materials, says uniform planarity mitigates these common defects. Techniques to achieve an even bond line and prevent substrate tilt include stitching and trimming wire bonds, but these can present integration challenges.

Indium’s InFORMS is designed to deliver precision bond line control and soldering in one shot. InFORMS acts as an embedded non-reflowing material within bulk solder. Its preforms and solder ribbon are reinforced matrix solder composites. Indium claims that inFORMS provides precise, repeatable standoff heights, ensuring more than four times the reliability of solder-only preform solutions as a result of reduced stress concentration, mitigated delamination and increased fatigue resistance that can withstand 3,500 thermal cycles.

Source: Indium

source https://chargedevs.com/newswire/solder-redefined-indiums-materials-provide-ev-power-electronics-solutions/

Monday, 28 September 2020

Anzode gets $1.7-million CEC grant for non-lithium batteries

Battery startup Anzode has received a $1.7-million award for a three-year effort to develop a new generation of non-lithium batteries, as part of the California Energy Commission (CEC) Grant Funding Opportunity “Developing non-Lithium Ion Energy Storage Technologies to Support California’s Clean Energy Goals.” The CEC has awarded almost $11 million for developers of energy storage technologies other than lithium-ion batteries to meet California’s 100% clean energy statutory requirement and the need for a diverse set of longer-duration storage technologies.

“Anzode’s scientists are working hard to address energy challenges in California and beyond,” said Anzode CEO Sebastien Belanger. “Anzode is building a generation of inexpensive green batteries that are safer for the environment. Our rechargeable zinc-manganese batteries provide great performance and safety and are much cheaper than lithium, making them a viable solution for backup power and energy storage. Future generations of our technology could even find their way into automobiles. This grant will enable Anzode to accelerate its design, prototyping and manufacturing tests.”

Anzode’s batteries use inexpensive materials, which the company says translates into a 70% cost advantage when compared to lithium-ion and gas generators for a given amount of energy. Zinc has long been considered an ideal battery electrode due to its high power and energy density, low cost, global availability, environmental characteristics and ease of recycling. Similarly, manganese is an abundant, safe, inexpensive and widely used element. Anzode’s technology stabilizes both metals and turns them into a rechargeable battery.

Source: Anzode

source https://chargedevs.com/newswire/anzode-gets-1-7-million-cec-grant-for-non-lithium-batteries/

Li-Cycle to build battery recycling hub in upstate New York

Battery recycling specialist Li-Cycle will invest over $175 million dollars in a lithium-ion battery recycling “Hub” at Eastman Business Park in upstate New York. The new facility will work in conjunction with Li-Cycle’s “Spoke” facility, which is already located at the Rochester site. Li-Cycle plans to begin construction on the Hub facility in 2021.

Li-Cycle’s Spoke and Hub operations will complement each other. There will be several US-based Spokes that aggregate and refine spent Li-ion batteries, separating the materials. Li-Cycle’s Rochester Spoke, due to open this fall, will be capable of shredding up to 5,000 tons of used batteries per year. Ultimately, the Hub operation in Rochester will receive battery materials from the Rochester Spoke and similar operations across the US, and process them further for use as raw materials in future manufacturing, including for new batteries.

SEE ALSO: Q&A with Li-Cycle CEO Ajay Kochhar

Li-Cycle claims that its process recovers 80 to 100% of all materials found in Li-ion batteries with no wastewater discharge. Recovered materials are either processed to the point of being reusable in battery production or other applications, or sent for further processing to other recyclers (e.g. steel and plastics). The company processes all types of Li-ion batteries used in electronic devices, EVs and energy storage.

Li-Cycle co-founder Tim Johnston said, “We are excited to be able to announce Rochester as the location of Li-Cycle’s first commercial Hub refinery. This facility will enable sustainable closed-loop production of critical materials for the battery industry, such as cobalt, nickel and lithium, right here in North America, supporting the development of EVs and other sustainable energy applications. We deeply appreciate the continued support of the local community, government agencies and Kodak in the development of this project.”

“This international partnership with Li-Cycle will foster the supply chain of lithium-ion batteries, which are in high demand, and will further expand the thriving energy storage industry in the region,” said New York Governor Andrew Cuomo.

Source: NY State Governor’s Office

source https://chargedevs.com/newswire/li-cycle-to-build-battery-recycling-hub-in-upstate-new-york/

Proterra’s ZX5 next-generation electric transit bus

Proterra has sold electric buses to over 120 customers in North America—more than any other manufacturer, the company claims. Now Proterra has introduced its fifth-generation battery-electric transit vehicle, the Proterra ZX5 electric bus.

The ZX5 is available in 35-foot and 40-foot versions, and with battery capacity of 220, 440 or 660 kWh. The 660 kWh option (40-foot version only) delivers up to 329 miles of range.

Compared to Proterra’s previous generation, the new ZX5 features a more streamlined body design, a lower vehicle height, new shocks and enhanced ergonomics designed to provide riders and drivers with a smoother riding experience. There’s also an additional front charging port for greater flexibility.

The ZX5 also offers faster acceleration and greater horsepower than earlier Proterra models. It can be configured with Proterra’s standard ProDrive drivetrain or its dual-motor DuoPower drivetrain. Proterra says its DuoPower drivetrain delivers nearly twice the horsepower and five times better fuel efficiency than a standard diesel engine. The DuoPower drivetrain’s two electric motors deliver 550 hp, accelerating a ZX5 bus from 0-20 mph in under six seconds. The DuoPower drivetrain can also propel a bus up a 25% grade, making it a good option for routes with steep hills.

Proterra’s battery systems are designed and manufactured at Proterra’s California battery manufacturing facility, and have logged over 13 million miles in mass transit service.

“A decade ago, Proterra delivered its first battery-electric transit bus. We were at the start of the transportation electrification revolution in North America,” said Proterra CEO Jack Allen. “As more cities and states make the commitment to 100% zero-emission fleets, Proterra is introducing new vehicle and battery technology to meet the needs of our customers. Our fifth-generation electric transit vehicle, the Proterra ZX5, is designed to tackle the toughest routes and terrains across North America.”

Source: Proterra

source https://chargedevs.com/newswire/proterras-zx5-next-generation-electric-transit-bus/

Considerations for selecting automotive-grade multilayer ceramic capacitors in EVs

Sponsored by Knowles Precision Devices

The worldwide electric vehicle (EV) market is exploding in demand and mainstream adoption as governments push for fuel economy improvements and automotive companies look for new market opportunities. According to Forbes, “by 2020, EVs are likely to cost the same as conventional fuel powered equivalents.” Major manufacturers – like General Motors, Toyota, and BMW – plan to release “a mouthwatering potential of 400 models and estimated global sales of 25 million by 2025.” For EV design engineers and purchasing agents, this drive towards increased electrification results in the challenge of finding cutting-edge components that can handle increasing temperatures, voltage, and power without sacrificing reliability, availability, and footprint.

Multilayer ceramic capacitors (MLCCs) are commonly used in EV electronics and subsystems because of their high temperature ratings, tiny size, and easy surface mount form factor. In order to help you choose the right automotive-grade capacitors for your EV project, this whitepaper discusses the key considerations and certifications for EV components, common use cases in EV subsystems, and capacitor requirements for specific applications.

source https://chargedevs.com/newswire/considerations-for-selecting-automotive-grade-multilayer-ceramic-capacitors-in-evs/

Charging network ChargePoint to go public in $2.4-billion deal

EVSE manufacturer and charging network operator ChargePoint plans to go public via the trendy vehicle of a special purpose acquisition company. ChargePoint will merge with Switchback Energy Acquisition Corporation (NYSE: SBE) to form a company called ChargePoint Holdings, which will be listed on the NYSE.

The boards of both companies have unanimously approved the transaction, which is expected to close by the end of this year.

The deal values ChargePoint at an enterprise value of $2.4 billion. The company plans to use the proceeds to expand its reach in North America and Europe, further enhance its technology portfolio and scale up its commercial, fleet and residential businesses.

Founded in 2007, ChargePoint operates in just about every segment of the charging business. Its capital-light business model is based on providing site hosts with everything they need to electrify their parking spaces: networked charging hardware, software subscriptions and support services. The company’s network includes over 115,000 public and private charging points, as well as access to an additional 133,000 public chargers through network roaming arrangements.

“For thirteen years we have been singularly focused on our vision to move all people and goods on electricity, and that has never been more relevant than it is today,” said ChargePoint CEO Pasquale Romano. “We’ve pioneered networked charging and are resolute in our aim to usher in the transition to mass EV adoption by electrifying one parking spot at a time. Today, we are a charging market leader thanks to a winning business model, a complete portfolio and thousands of brands that have realized that EV charging is essential, good for business and aligned with their corporate and sustainability goals. Our technology charges all EVs, from passenger vehicles to delivery fleets, so there is no need to choose winners in electric mobility. We see ourselves as an index for the entire category.”

“The EV charging industry is accelerating and it is expected that charging infrastructure investment will be $190 billion by 2030,” said Switchback CEO Scott McNeill. “As a first mover in the space, ChargePoint has distinguished itself as the number-one EV charging network, and is well positioned to deliver mission-critical charging infrastructure as the expected transition to electric mobility accelerates. ChargePoint has a proven and capital-light business model that combines hardware and high-margin, recurring software subscriptions and services with strong customer relationships.”

Source: ChargePoint

source https://chargedevs.com/newswire/charging-network-chargepoint-to-go-public-in-2-4-billion-deal/

Former Volvo Trucks exec launches electric truck startup

Patrick Collignon, former COO for Volvo Trucks North and South America, has launched a startup called Trova Commercial Vehicles. The new company, which is located at a business incubation center in Fairlawn, Virginia, offers customized engineering and manufacturing expertise for electric trucks. TrovaCV will offer its industrial model and manufacturing capability to other commercial vehicle OEMs, and also develop its own fully electric vehicle.

Collignon has more than 30 years of international experience in the commercial vehicle industry with GM and the Volvo Group. He has incubated several companies, and held board positions in economic and industry federations. In 2007, he was instrumental in making the Volvo plant in Ghent, Belgium, a carbon-neutral automotive plant.

“This is an exciting time, as the electric commercial vehicle market is being reshaped,” says Collignon, founder and CEO of the new company. “While technology and innovation have made it possible to convert fuel-powered commercial vehicles into electric vehicles, we haven’t seen a production model capable of producing the required volume of fully electric commercial vehicles to meet the demand. We believe that our engineering approach will offer OEMs the opportunity to build a higher volume of electric vehicles at a lower cost. At the same time, we will utilize our chassis design experience to achieve a complete EV build design from the ground up.”

Source: Trova Commercial Vehicles

source https://chargedevs.com/newswire/former-volvo-trucks-exec-launches-electric-truck-startup/

Friday, 25 September 2020

Digatron and DSA launch end-of-line tester for lithium battery production

Digatron and DSA have designed a solution for end-of-line testing for lithium battery production.

The two companies developed a modular end-of-line test solution that allows customers to select pre-defined test regime modules per their requirements. Battery EOL Tester supports the entire workflow of EOL testing by offering customized communication and testing solutions, including electrical test, leakage test, BMS configuration, and more.

“For us, electromobility represents an interesting growing market segment and we are pleased to have gained an experienced partner from the automotive industry in DSA,” said Digatron VP Friedrich Grupe.

“The growing market of electric mobility means that car manufacturers and suppliers are faced with the task of identifying and integrating high-performance systems for high-voltage battery testing,” added DSA’s Michael Kohlhaas. “We are confident that with the test system developed together with Digatron, we can offer a solution that is optimally tailored to the requirements of our customers.”

Source: Digatron

source https://chargedevs.com/newswire/digatron-and-dsa-launch-end-of-line-tester-for-lithium-battery-production/

Luxury travel trailer features solar panels, EV charging, battery storage

Volta Power Systems is providing a lithium-ion battery system for the 2021 Living Vehicle luxury travel trailer. The Living Vehicle system offers up to 3,080 watts of solar power and 47.6 kWh of energy storage. Living Vehicle owners can also charge their EVs using optional 240-volt exportable power.

Living Vehicle’s luxury trailers are designed to enable owners to maximize their time off-grid. They feature energy storage, redundant generation and water conservation technology to preserve and extend utility resources for days or weeks while still supporting high-power amenities such as air-conditioning, appliances and entertainment.

Living Vehicle is releasing three different models for 2021, all with Volta systems and solar power systems. The Volta system can charge from shore power, solar panels, an optional alternator (installed in a gasoline or diesel tow vehicle), or an optional Cummins generator. These layers of redundant power supply can also provide backup power in severe weather or natural disasters.

Source: Volta Power Systems via Green Car Congress

source https://chargedevs.com/newswire/luxury-travel-trailer-features-solar-panels-ev-charging-battery-storage/

Toronto operating 60 electric buses from 3 vendors

The Toronto Transit Commission (TTC), which claims to have the largest fleet of electric buses in North America, is now deploying its third new electric bus model.

The TTC has approved procurement of 60 electric buses from three manufacturers: New Flyer, Proterra and BYD Canada. Approximately 35 e-buses are already in service across the city. The remaining 25 are currently undergoing final testing and commissioning activities, and are expected to be in service by the end of September.

The differences among the three bus models, including charging and overall performance, will be put to the test in a head-to-head comparison, and the TTC will use the results to inform its future procurements of battery-electric buses.

TTC outfitted its Arrow Road Garage with charging infrastructure for its New Flyer vehicles, and equipped its Mount Dennis Garage with the same charging technology for its Proterra buses. Whereas the New Flyer and Proterra buses use DC charging, the BYD vehicles use an AC system. They will based out of the TTC’s Eglinton Bus Division.

Toronto aims to reduce its local greenhouse gas emissions by 80 percent by 2050. As a part of that strategy, it has set a target date of 2040 to electrify all its transit buses. The Government of Canada and the City of Toronto have invested $140 million in this project under the federal Public Transit Infrastructure Fund (PTIF).

“Our government’s investment in the TTC’s electric bus pilot program is a sign of our commitment to made-in-Canada clean technology and an important step toward our target of 5,000 electric buses in Canada’s fleets over the next five years,” said The Honourable Catherine McKenna, Minister of Infrastructure and Communities.

“Electrification is the future of public transit, and I’m proud that the TTC has been established as an industry leader in this regard, as the owner of North America’s largest fleet of e-buses,” said TTC Chair Jaye Robinson. “The TTC Board wholeheartedly supports the TTC’s forward-thinking plan to achieve a zero-emissions fleet by 2040.”

Source: Toronto Transit Commission

source https://chargedevs.com/newswire/toronto-operating-60-electric-buses-from-3-vendors/

Punch Powertrain and Groupe PSA launch electrification joint venture

Punch Powertrain and Groupe PSA have launched a new joint venture to design, manufacture, and supply Punch Powertrain’s DT2 dual-clutch transmission for the next generation of hybrids. The business will initially supply Groupe PSA’s global operations, and aims to eventually supply other vehicle manufacturers. Elias van Wijk, previously CTO of Punch Powertrain, was named CEO of the new company.

The DT2 is a departure from 48-volt and high-voltage hybrid infrastructures as a design base. According to Punch, this allows integration and optimization of an electric motor for hybrid vehicle applications that enable intervals of full electrically powered driving.

The company is headquartered in Sint-Truiden, Belgium, at the site of Punch Powertrain, and has a second location in Eindhoven. Earlier this year, the two companies launched another joint venture, dedicated to assembly of the DT2 electrified transmission at Groupe PSA’s facility in Metz, France.

“This second joint venture with Groupe PSA fully aligns with our vision that ‘Our powertrains drive a sustainable world’ through technology innovation,” said Punch Powertrain CEO Jorge Solis. “This new venture will spearhead the industrialization of our next generation of transmissions for hybrid electric vehicles, providing broader availability of affordable electrified powertrains on global markets.”

Source: Punch Powertrain

source https://chargedevs.com/newswire/punch-powertrain-and-groupe-psa-launch-electrification-joint-venture/

Thursday, 24 September 2020

California Governor issues order to ban the sale of new fossil fuel vehicles by 2035

California Governor Gavin Newsom has issued an executive order requiring all new passenger vehicles sold in the state to be zero-emission by 2035. Some 15 countries have announced proposals to phase out legacy vehicles (and the UK recently brought its proposed ban forward to 2030), but California will be the first US state to do so.

The California Air Resources Board will develop regulations to mandate that all sales of new passenger cars and trucks be zero-emission by 2035. For medium- and heavy-duty vehicles, the deadline will be 2045 “where feasible,” except for drayage trucks, which must go zero-emission by 2035. CARB has already approved new regulations requiring truck manufacturers to begin the transition to zero emissions in 2024.

To ensure the needed charging infrastructure to support zero-emission vehicles, the governor’s order requires state agencies, in partnership with the private sector, to accelerate deployment of affordable fueling and charging options.

The executive order will not prevent Californians from owning gasoline-powered cars or selling them on the used car market. “We’re not taking anything away. We’re providing an abundance of new choices and new technology,” said Newsom during a news conference, where he signed the executive order on the hood of a Ford Mustang Mach-E.

The San Francisco Chronicle noted that imposing the ban by way of an executive order could allow Newsom to avoid a pitched battle in the state legislature, where the oil industry commands plenty of influence.

The order includes several other anti-pollution measures that oil companies may not like. According to the governor’s office, it calls for new health and safety regulations to protect workers and communities from the impacts of oil extraction, supports companies that transition their oil production operations to cleaner alternatives, and directs the state to make sure taxpayers are not stuck with the bill to safely close and remediate former oil fields. The Governor is also asking the legislature to end the issuance of new fracking permits by 2024.

“This is the most impactful step our state can take to fight climate change,” said Governor Newsom. “For too many decades, we have allowed cars to pollute the air that our children and families breathe. Californians shouldn’t have to worry if our cars are giving our kids asthma. Our cars shouldn’t make wildfires worse—and create more days filled with smoky air. Cars shouldn’t melt glaciers or raise sea levels threatening our cherished beaches and coastlines.”

Sources: California Governor’s Office, San Francisco Chronicle

source https://chargedevs.com/newswire/california-governor-issues-order-to-ban-the-sale-of-new-fossil-fuel-vehicles-by-2035/

Tesla Battery Day: a raft of tech advances will deliver cost reductions worth waiting for

We’re used to extremely ambitious (not to say unrealistic) timelines from Tesla—a new Terafactory in a few months, a fleet of Robotaxis before the end of the year—so Elon Musk’s measured, conservative predictions at the long-awaited Battery Day event caught the mainstream press on the wrong foot.

“In three years…we can do a $25,000 car that will be basically on par [with], maybe slightly better than, a comparable gasoline car,” said the uncharacteristically cautious Musk. Three years? Slightly better? As one analyst put it, to be a “long-term investor” these days means looking ahead one year. This wasn’t the blockbuster news the masses were expecting, and TSLA stock got hammered.

It may just be that Musk has matured, and adopted a new policy of under-promising and over-delivering. Another thing that’s going on here is that, as usual, our colleagues in the general-interest and financial media have missed the real implications of Tesla’s news. How fortunate that we more tech-savvy EV journalists are here to enlighten them, and you, dear readers.

So, to sum up the message of Battery Day in plain language: The Oil Age is ending.

The main event was the unveiling of Tesla’s new, in-house battery cell, dubbed the Tesla 4680 cell in honor of its dimensions (46 mm by 80 mm). The larger cell offers five times the energy capacity, and six times the power capacity of Tesla’s previous cells (capacity, not density—Tesla did not reveal the amount of improvement in energy density).

Simply making the cell larger allows an increase in capacity and a reduction in cost. Tesla claims that the larger form factor will increase vehicle range by 16%, and reduce cost per kWh by 14%. However, making the cell larger makes thermal management more challenging, which Tesla has dealt with by creating a new tabless cell design that offers much less resistance compared to existing designs.

The new cell design is only part of the story. Elon Musk and Drew Baglino, Tesla’s Senior VP of Powertrain and Energy Engineering, described important innovations in at least four other aspects of battery production:

- a new type of silicon that will allow more Si to be used in the anode in place of graphite, reducing costs by 5%

- a new cathode production process that eliminates wastewater and uses nickel more efficiently (12% cost savings here)

- a new battery pack that forms a structural part of the vehicle, linking the large underbody castings, which could reduce overall vehicle mass by 10%

- improved and simplified manufacturing processes, including the dry coating electrode process pioneered by Maxwell, which Elon Musk said is “close to working,” and a super high-speed assembly process that is supposed to increase production line output sevenfold

By combining all these innovations, Tesla hopes to cut the cost per kWh of battery packs in half within the next three years or so. Will that get us to the Grail? Absolutely. Industry observers are predicting that the EV industry will breach the holy $100/kWh number by 2023, but some believe that Tesla is already very close to that figure. The new, more circumspect Musk didn’t specify an exact price target, but he did say that Tesla’s three-year plan will bring the price below Grail level.

Napkins covered with scrawled math are all over the table. The Verge predicts Tesla’s $25,000 EV will have a $6,000 battery pack (a reduction of almost 100% from current costs in the industry). Electrek’s Fred Lambert, a keen Tesla-watcher, is more sanguine—he believes Tesla’s current pack-level cost is around $110/kWh, so halving the cost would put the price of a 50 kWh pack at only $2,500—a tenth of the cost of the original Model S pack.

How would a $25,000 EV (which might just be called Model 2) affect the global auto industry? According to The Verge, the average EV on the US market cost $55,600 in 2019, considerably pricier than the average dinosaur burner at $36,600. The numbers represent some sweeping generalizations and a large dose of uncertainty, but if Tesla comes anywhere close to reaching its announced goals, we should start to see gas cars sitting out in the rain with the last of the cathode-ray-tube TVs sometime in 2023.

Tesla will build the next-gen batteries in Fremont. The company hopes to be producing 10 GWh per annum within about a year, 100 GWh by 2023, and 3,000 GWh by 2030.

Massive vertical integration is the order of the day. Tesla is talking about mining its own lithium (and, naturally, making production of the light white stuff more efficient, cheaper and greener).

Every Tesla event has to have a bit of lagniappe, and this time around it was the Model S Plaid, which will be the highest-performance Model S ever. In fact, the tri-motor, all-wheel drive sedan will be the quickest production car ever, with a 0-60 mph time of less than two seconds, as well as a 200 mph top speed, over 520 miles of range, and a starting price of $139,990. The super-Tesla isn’t at the top of the priority list, however—Musk confirmed that production is expected in “late 2021.”

Sources: Tesla, Electrek, The Verge, EVannex

source https://chargedevs.com/newswire/tesla-battery-day-a-raft-of-tech-advances-will-deliver-cost-reductions-worth-waiting-for/

Wednesday, 23 September 2020

Volkswagen ID.4, Nissan Ariya bring EV drive to compact crossovers … chasing Tesla Model Y

Can new electric entries in a hugely popular segment convince U.S. buyers to buy EVs from Nissan and VW as family vehicles?

Two new battery-electric models from major global car brands are about to bring electric cars into a category where they’ve been notably absent: family crossover utility vehicles. The 2021 Volkswagen ID.4 and 2022 Nissan Ariya will join the Tesla Model Y that’s already on sale to bring EV transport to tens of thousands of new U.S. buyers who’d never consider a compact hatchback for a family car. At least that’s the goal.

The VW ID.4, unveiled globally today after months of leaks, is already in early production in Zwickau, Germany. It will be exported to the U.S. for roughly two years, until it goes into production in the Volkswagen plant in Chattanooga, Tennessee, that now builds larger VW crossover models.

The Nissan Ariya, which made its global debut in July, will be built only in Japan. It will serve as Nissan’s “halo” car, the first of many vehicles on all-new battery-electric underpinnings to be shared by Nissan and its partners Renault and Mitsubishi.

The new VW and Nissan join the Tesla Model Y, also a five-seat crossover, which went on sale early this year. Other entries in the segment include the 2021 Ford Mustang Mach-E, which is to go on sale within months, and future models from Hyundai, Kia, and probably a few General Motors brands.

Why crossovers matter

Compact crossover utility vehicles have become the default vehicle choice for couples and small families. They’re roughly as popular as full-size pickup trucks, and have supplanted sedans and wagons in driveways and parking lots all over the U.S. Since they first launched in the mid-1990s, crossovers have combined the advantages of larger, truck-based sport-utility vehicles (SUVs) with vehicles built on car platforms—giving them better handling, more comfortable rides, and competitive fuel economy.

With five seats, a capacious load bay, optional all-wheel drive, and a high seating position, these crossovers are practical, affordable, and hugely popular. Four million were sold to U.S. drivers last year, and the average price paid for one in August was $30,263, according to sales transaction data collated by Kelley Blue Book.

Multiple makers, led by Tesla, see five-seat crossovers as the way to bring mass-market buyers to EVs. Offer a familiar type of vehicle, with a more spacious cabin than its gasoline equivalent, the same cargo space, and more than 200 miles of range, and car shoppers will start to consider a car that plugs in—which they wouldn’t when the only EV was a hatchback.

Or so goes the argument.

Volkswagen ID.4: VW’s most important new EV

Among makers, VW has by far the most aggressive goals and highest volumes planned for the dozens of electric models it will launch under multiple brands by 2025.

The new crossover EV is the linchpin of that strategy, with the company saying it will sell half a million ID.4 electric crossovers a year by 2025, fully one-third of the 1.5 million EVs it expects to deliver annually. It will be built not only in Germany and the U.S., but also in China.

In previews for media held earlier in September, VW of America executives underscored their belief the ID.4 can compete head-to-head with the most popular compact crossovers in the country. Those include the Ford Escape, Honda CR-V, Nissan Rogue, Subaru Forester, and Toyota RAV4.

Volkswagen believes the ID.4 will sell on its merits: Its internal tests show the electric utility is faster, quieter, and handles better than the most popular gasoline entries. Asked if the ID.4 would cannibalize sales of its own compact crossover with a combustion engine, the VW Tiguan, VWoA CEO Scott Keogh suggested it would bring new buyers to VW, including drivers of vehicles like the Subaru Forester—which comes from a brand that lags significantly in EV offerings.

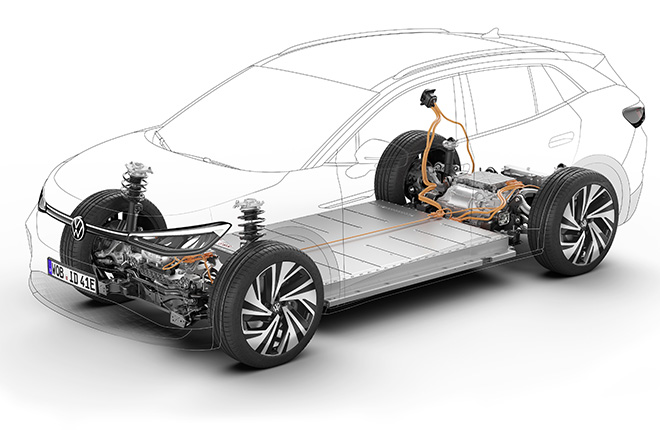

For U.S. buyers, the “1st Edition” launch version of the VW ID.4 will feature an 82-kilowatt-hour liquid-cooled battery pack, a 150-kilowatt (201-horsepower) motor producing 228 pound-feet of torque that drives the rear wheels, and an estimated EPA range of 250 miles. It will offer towing capacity of 2,700 pounds, an important capability for some buyers—though towing will cut into range substantially.

All-wheel drive will arrive during 2021 as an option for ID.4s in the U.S., with a second motor rated at 75 kw (101 hp) to power the front wheels. VW did not comment on projected EPA range for the AWD version.

All versions of the car will offer DC fast charging at up to 125 kw through a CCS connector. Just two days before the ID.4’s global launch, Volkswagen announced it would provide ID.4 buyers with three years of unlimited fast charging on the Electrify America nationwide network. How well the EA network will function for drivers new to EVs as ID.4 sales accelerate in 2021 remains to be seen; the ease of use and ubiquity of the Tesla Supercharger network is a high bar to match.

For simplicity, only seven basic build configurations of the ID.4 will be offered to U.S. buyers. All versions will include adaptive cruise control, lane centering, and a variety of other advanced electronic safety and infotainment systems. VW says more than 90 percent of its 650 U.S. dealers have signed up to offer the ID.4.

Prices for the low-end Volkswagen ID.4 Pro will start at $39,995 before national, state, and local incentives. (VW says in two years, once localized ID.4 production starts in Chattanooga, that base price will fall to roughly $35,000.) A $399 monthly lease is also available with a $3,300 down payment for buyers driving only 10,000 miles a year.

Once a $7,500 federal tax credit, state purchase incentives, and savings from driving on electricity versus gasoline are factored in, VW says the effective price of an ID.4 can fall below $30,000—making it competitive with the high-volume crossovers.

Whether buyers do the math that way remains to be seen.

Ariya: Nissan’s Take 2 on EVs

It’s been almost 10 years since the first Nissan Leaf electric car rolled off the production lines in October 2010. In July, the Leaf’s successor was formally revealed.

It’s the 2022 Nissan Ariya (pronounced “aria”), a compact crossover utility vehicle with a promised 300 miles of range in at least one version, available all-wheel drive, and the lines of a sleek SUV.

First previewed by a patent filling in April 2019, the Ariya Concept broke cover at the Tokyo Motor Show in October 2019. For a concept vehicle, it looked remarkably ready for production, including actual door handles and real side mirrors—two things often missing from concept vehicles. It had very large, very extravagant wheels, but that was about it. Indeed, the production car is all but identical.

Nissan says the Ariya will be offered with two battery capacities in the U.S.: 65 and 90 kilowatt-hours. Both packs are liquid-cooled, meaning Nissan has learned its lesson about battery durability after using passive air cooling in the half-million Leafs it has built over the past 10 years.

While the Ariya won’t reach North America until late in 2021, Nissan has taken the unusual step of estimating its EPA range ratings already. The smaller 65-kwh pack will be rated at 210 miles or more in front-wheel-drive form, it says, and at least 200 miles with all-wheel drive (which Nissan labels e-4orce). The larger 90-kwh pack will deliver 300 miles in FWD form, and 270 miles with AWD.

As for charging, the Ariya will the Combined Charging System (CCS) standard in North America, in both 125- and 350-kilowatt versions. That means Nissan will walk away from the CHAdeMO system it pioneered in the U.S., though that will remain the charging standard for Ariyas sold in certain Asian markets.

The company will pitch performance as one of the Aria’s main attractions, with the high-spec AWD 90-kwh model accelerating from 0 to 60 mph in 4.8 seconds. Expect to see that compared to the same specification for Nissan’s legendary Z car, which goes from 0 to 60 in 4.7 seconds.

U.S. pricing for the 2022 Nissan Ariya will start “around $40,000,” according to company officials.

Compact footprint, mid-size cabin

While the Ariya looks big, it’s actually shorter than either the Ford Mustang Mach-E or the Tesla Model Y. It’s the length of the Nissan Rogue conventional crossover, but the company says it’s a compact vehicle with mid-size cabin space—making it “the most spacious vehicle in the class,” according to Nissan.

That comes from a short nose and a long cabin, the same formula used by the far pricier Jaguar I-Pace. Like the Volkswagen ID.4, the Ariya has no front trunk under the hood. But by putting all the cabin heating and air-conditioning gear under there—along with a drive motor and power electronics—Nissan didn’t have to connect the console between the seats to the dash. The resulting open area, it says, adds to the cabin’s sense of spaciousness.

The interior has a big 12.3-inch landscape touchscreen display stretching from behind the steering wheel to the center of the dash. Nissan has largely eliminated physical buttons, except for a knob that lets users alter vehicle settings and use the infotainment system. Climate controls are touch-sensitive icons with haptic feedback at the bottom. Tesla can pull that off; can Nissan?

Electronic systems are a necessity, and the Ariya will recognize each driver’s smartphone and adjust presets for that individual. The new EV will also pioneer the next generation of the company’s ProPilot driver-assist technologies,

A slew of coming crossovers

Ten years into the electric-car transition, a few things have become clear.

- More than 200 miles of range is the price of entry, and a 300-mile version is probably needed to reassure nervous shoppers and attract attention;

- Fast charging at 125 kw is the minimum for the next few years, and 350-kw charging is coming on fast;

- $40,000 is the entry price point for an EV crossover, but it still takes convoluted math to produce an “effective price” that’s as low as the highest-selling entries; and

- Electric pickup trucks may get the buzz, but compact crossovers are where automakers see EV volume coming.

Tesla itself offered the first entry in the electric compact crossover segment, but unlike its other vehicles, the Model Y has less than a year of lead time on both the Ford Mustang Mach-E and the Volkswagen ID.4. Nissan has chosen to sell the Ariya first outside North America, with the U.S. not getting its electric SUV until the 2022 model year.

Today, no large global maker can offer the mix of long range, seamless fast charging, and general cool factor that Tesla does. Whether any of them can catch and exceed Tesla in this crucial volume segment will be a fascinating fight to follow.

source https://chargedevs.com/features/volkswagen-id-4-nissan-ariya-bring-ev-drive-to-compact-crossovers-chasing-tesla-model-y/

Virtual Peaker and Fermata Energy aim to bring V2G technology to utilities

Kentucky-based Virtual Peaker and Fermata Energy have announced a partnership to integrate Fermata’s vehicle-to-grid (V2G) technology with Virtual Peaker’s residential demand response platform, which is currently in use by several US utilities.

Virtual Peaker’s Distributed Energy Resource Management System (DERMS) application is a cloud-based energy management platform that can connect to any in-home smart device to allow utilities to run residential demand response programs. Fermata Energy’s bidirectional charging system, which conforms to the new UL 9741 Standard for Bidirectional EV Charging System Equipment, allows vehicle batteries to be charged while returning excess energy to the electrical grid.

This two-way system delivers energy to an EV at off-peak times, and returns stored power to the grid during peak demand times.

“The new relationship with Fermata Energy gives Virtual Peaker an early entry into the V2G market, which we expect will experience explosive growth in the coming years as more Americans understand the value of preserving renewable energy sources and reducing our dependence on fossil fuels,” said William (Bill) Burke, founder and CEO of Virtual Peaker.

“Fermata Energy’s turnkey system accelerates the transition to a clean-energy economy, creating abundant power storage that can be deployed quickly and at scale,” said David Slutzky, founder and CEO of Fermata Energy. “The partnership with Virtual Peaker demonstrates an exciting solution to two of today’s major challenges: how to further integrate clean, renewable energy, and the rapid adoption of clean transportation.”

Sources: Virtual Peaker, Fermata Energy

source https://chargedevs.com/newswire/virtual-peaker-and-fermata-energy-aim-to-bring-v2g-technology-to-utilities/

Tuesday, 22 September 2020

Nissan achieves breakthrough in carbon fiber parts production

Carbon fiber reinforced plastic (CFRP) was once seen as an ideal body material for EVs, because of its high strength and light weight. It was used in the Tesla Roadster and the BMW i3, but fell out of favor because of its high cost. Now Nissan has developed a new production process that speeds up the development of CFRP car parts.

Nissan aims to use the new process to mass-produce CFRP parts and employ them in more cars. The company says its innovation can cut the lead time to develop such components by as much as half, and cycle time for molding by about 80%, compared with conventional methods.

Nissan found a new approach to the existing production method known as compression resin transfer molding, which involves forming carbon fiber into shape and setting it in a die with a slight gap between the upper die and the carbon fibers. Resin is then injected into the fiber and left to harden.

Nissan’s engineers developed techniques to simulate the permeability of the resin in carbon fiber while visualizing resin flow behavior in a die using an in-die temperature sensor and a transparent die. The result of the simulation was a high-quality component with shorter development time.

Source: Nissan

source https://chargedevs.com/newswire/nissan-achieves-breakthrough-in-carbon-fiber-parts-production/

Scania introduces range of electric trucks

Scania, a major Swedish manufacturer of commercial vehicles, has announced a pair of new plug-in trucks: a plug-in hybrid and a fully electric model.

Both versions are offered with L- and P-series cabs, and can be configured for general cargo, temperature-controlled transport, or for specialty applications such as hooklifts, tippers, concrete mixers, refuse collectors and fire and rescue vehicles.

The fully electric truck can be configured with five batteries, for a total capacity of 165 kWh, or nine batteries, for 300 kWh. Maximum range is 250 km. One battery sits in the former engine tunnel, and the remaining four or eight are placed along the side of the chassis. A 230 kW electric motor delivers 310 hp and 2,200 Nm of torque.

CCS fast charging is standard, at rates up to 130 kW. Scania says charging time from 0 to 80 percent is approximately 40 minutes for the five-battery option and approximately 65 minutes for the nine-battery option.

The PHEV truck has three batteries, with total capacity of 90 kWh, and features a 115 kW electric motor along with a 280-360 hp combustion engine. Electric range is 60 km.

“We will over the coming years annually launch electric vehicles for the entire product range, and we are presently reorganizing our production towards that end,” says Scania CEO Henrik Henriksson. “In a few years’ time, we will also introduce long-distance electric trucks adapted for fast charging during drivers’ compulsory 45-minute rest periods.”

“Although electrified vehicles in certain aspects represent a new technology, we’ve taken all possible steps to ensure that we apply the same unwavering uptime criteria as for our other trucks,” says Anders Lampinen, Director, New Technologies. “Scania signifies premium quality and needless to say that characterises our electrified trucks as well.”

Source: Scania

source https://chargedevs.com/newswire/scania-introduces-range-of-electric-trucks/

Minnesota offers grants to deploy up to 38 fast charging stations

The Minnesota Pollution Control Agency (MPCA) has announced that it will fund the installation of up to 38 additional fast charging stations in Greater Minnesota, extending the existing EV highway corridor network by more than 2,500 miles. Chargers are to be placed 30 to 70 miles apart along 7 proposed corridors.

The new $2.6-million grant opportunity leverages funds from the national Volkswagen settlement. Applicants will be asked to place 5 to 7 fast chargers along specific segments of roadway. Applications for grant funds are due by November 25. Details are available at MPCA’s web site.

“When we’ve asked Minnesotans how we should spend funds from the Volkswagen settlement, building EV infrastructure is one of the most widely supported proposals,” said Rebecca Place, MPCA’s Electric Vehicle Program Administrator. “We are planning for the future by ensuring each charging station has a back-up station and enough electrical capacity for future expansion.”

Over the last two years, MPCA has expanded Minnesota’s EV charging network along highway corridors by approximately 1,100 miles and funded 25 Level 2 charging stations, each with two charging ports, in local communities.

“Minnesota has set ambitious goals for powering 20 percent of light-duty cars with electricity by 2030 and reducing our greenhouse gas emissions by 80 percent by 2050,” said MPCA Commissioner Laura Bishop. “Funding infrastructure projects like this will help us reach our goals while supporting Minnesota’s green economy and our growing EV market.”

Source: Minnesota Pollution Control Agency

source https://chargedevs.com/newswire/minnesota-offers-grants-to-deploy-up-to-38-fast-charging-stations/

Monday, 21 September 2020

Encapsulant provides excellent corrosion protection of critical PCB components in EV electronics (Whitepaper)

Sponsored by Dymax Corporation

By Dr. Aysegul Kascatan Nebioglu and Chris Morrissey

Components on printed circuit boards or electronic modules in electric vehicles are often required to be covered with polymeric encapsulants to protect them against environmental conditions such as moisture, chemicals, and rapid and extreme temperature changes, while providing mechanical support and electrical insulation.

It is crucial for encapsulants to induce minimal stress on chips, wires, and other parts for the reliability of the electronic assemblies. Liquid encapsulants are typically based on epoxies, silicones, or light-curable materials. Epoxy formulations are rigid and utilize high loads of mineral fillers to lower bulk coefficient of thermal expansion (CTE) to match CTE of the substrates. However, since the organic epoxy has a higher CTE than the mineral fillers, it can move filler particles against the wires and create an abrasive effect on the wires, reducing the reliability of the parts. Silicones and light-curable encapsulants are typically more flexible and have low modulus than epoxies, therefore creating less stress on the components, wire bonds, and solder connections, including those found in circuit boards used in the operation of battery management systems (BMS).

A new dual-curable (light and moisture), 100% solids encapsulant that exhibits an excellent balance of properties is now available. While the key advantage of light-curable encapsulants is the ability to use a non-solvated, “green” (100% solids) material, secondary moisture cure allows curing of the material in shadow areas not available to UV light. This one-component material can also be shipped and stored at ambient conditions, so it does not require cold shipping and storage. Light-curable encapsulants can also provide significant benefits over conventional technologies, including very fast, tack-free curing, lower operating costs driven by lower labor needs, space savings, lower energy demand, and higher throughput. This material does not require heating to cure, which makes it an ideal choice for heat-sensitive substrates and very well-suited for wire bonding applications in EV BMS.

A white paper features the results of a study performed on liquid glop-top encapsulants that are placed over PCB components and wire bonds as a protective layer. The performance of this new dual-curable encapsulant against other light-curable materials and types of encapsulants in reliability tests, such as heat and humidity resistance (85oC / 85% RH), thermal shock resistance (-55oC to +125oC) and corrosion resistance against salt spray and chemicals, is outlined in detail.

Visit Dymax dual-cure EV encapsulant to download your copy.

source https://chargedevs.com/newswire/encapsulant-provides-excellent-corrosion-protection-of-critical-pcb-components-in-ev-electronics-whitepaper/

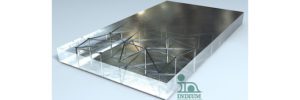

Consortium of auto suppliers launches multi-material EV battery casing project

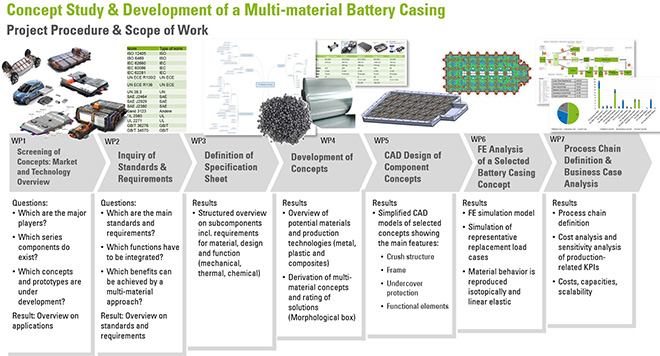

German engineering firm AZL is joining with an international consortium of automotive suppliers to develop a multi-material battery casing. The 8-month product development will start with an international market analysis and a concept study in which different multi-material component concepts and production scenarios will be developed and evaluated with regard to their costs. Finally, a multi-material battery casing will be designed, then manufactured as a prototype in a follow-up project.

“Battery casings are key components in EVs. The requirements are challenging, and very individual for different vehicle classes,” said Audi Project Manager Dr. Florian Meyer. “We are looking forward to the creative exchange with the cross-value chain and cross-material class consortium to find out how we can save weight and costs by using plastic-based multi-material solutions, versus status quo solutions made of metals.”

AZL will draw up a market overview with the industrial consortium that includes existing series components and concepts, and identifies the relevant manufacturers, users, suppliers and supply chains on the market. Standards and requirements for battery casings will be derived from the existing components, and the advantages of multi-material approaches will be evaluated. On the basis of detailed datasheets, various product concepts will be worked out and associated production scenarios for multi-material battery casings will be established. The participants can select component concepts for which CAD models, FEM analyses and process chains are developed and finally evaluated with regard to their production costs.

The project will kick off on October 22 via video conference. Interested companies can find further information on AZL’s web site.

Source: AZL

source https://chargedevs.com/newswire/consortium-of-auto-suppliers-launches-multi-material-ev-battery-casing-project/

Shaffhausen, Switzerland to deploy 15 Irizar e-buses

The historic city of Schaffhausen, Switzerland, is located on the River Rhine, which provides not only a picturesque setting, but a reliable source of hydroelectric power—an ideal source of green energy for the city’s new electric buses.

Switzerland’s Federal Office of Transport (the equivalent of our Federal Transit Administration) has tested and certified the electric buses, made by Spanish manufacturer Irizar. Further tests of the charging infrastructure are now underway.

Local transit agency VBSH ordered the two Irizar electric buses in March 2019, and installed a temporary charging station on one of the city’s main streets at the beginning of August. It is now in the process of installing charging infrastructure at the bus depot, which will have both an overnight charging station and a rapid charging station.

The city pans to deploy fifteen Irizar e-buses—seven 12-meter ie models and eight articulated ie tram models.

Irizar’s e-buses are in-house productions—almost all the components, including the electric powertrain, electronics, battery packs and communications systems, are built by companies belonging to the Irizar Group. The buses are assembled in Aduna, near San Sebastian, in the Basque region of northern Spain.

Source: Sustainable Bus

source https://chargedevs.com/newswire/shaffhausen-switzerland-to-deploy-15-irizar-e-buses/

Ford says electric F-150 will be “a workhorse,” will begin production in mid-2022

Many believe the tipping point for EVs in the US will occur when a selection of electric pickup trucks hits the market. Now Ford, the prime purveyor of pickups, has announced that it is moving ahead with its plans to produce an electric version of the F-150, the nation’s bestselling vehicle.

The Detroit Free Press reports that Ford plans to build a new 500,000-square-foot, $700-million plant at its historic Rouge complex. The new Rouge Electric Vehicle Center will support battery assembly and production of the F-150 PowerBoost hybrid and fully electric F-150, and will add 300 jobs.

Ford Chief Manufacturing Officer Gary Johnson told reporters flexibility is the reason for a separate EV-building facility. “We will use the current body and paint shop” in conjunction with the new building. He declined to specify manufacturing capacity, saying that demand will drive production volume.

“The building—it’s going up,” Johnson said. “Expectation is we’ll have the building completed sometime next summer. We’ll start doing our early prototype builds as part of our launch plans.”

“The electric F-150, which is undergoing tens of thousands of hours of torture testing and targeting millions of simulated, laboratory and real-world test miles, will be more powerful than any F-150 available today,” Ford said.

“This is the truck that’s going to lead Ford and the entire industry into a new era,” said Ford’s incoming CEO Jim Farley. “Simply put, this isn’t a gimmick. It’s a workhorse, not a show horse destined for a shiny garage filled with four other luxury cars. It’s not for ‘never nevers’ (never tow, never haul) it’s for serious truck owners.”

Kumar Galhotra, President of Ford’s Americas & International Markets Group, told the press that the new EV will be for the “work customer.” “They want the ability to “seriously power a work site for their tools.” Ford’s e-pickup will have “a giant frunk,” and “bidirectional power transfer, so you can…use the power for powering your home or the work site.”

It will also be “the fastest F-150 ever” in terms of 0-60 time, and “the most powerful. With the battery and the electric motors, it will have most torque of any F-150 we’ve ever built, and the torque will be instantaneous,” said Galhotra. “It totally changes the driving dynamics.”

Ford has released a new video that shows the prototype electric F-150 indulging in some rollicking off-road activity, and sprinting up a 60% grade.

The electric F-150 is to start rolling off the production line in Dearborn in mid-2022.

Source: Detroit Free Press, Electrek

source https://chargedevs.com/newswire/ford-says-electric-f-150-will-be-a-workhorse-will-begin-production-in-mid-2022/

Friday, 18 September 2020

In-Charge Energy to provide charging infrastructure for Navistar’s EV customers

NEXT eMobility Solutions, a business unit of Navistar International (NYSE: NAV), has signed a master services agreement with Los Angeles-based In-Charge Energy to provide charging infrastructure and consulting services to Navistar and its EV customers.

As fleet operators electrify, they are learning that purchasing EVs is just the beginning of the process—they slso need to consider maintenance, increased electricity demand, utility upgrades and other factors. NEXT eMobility, which launched last October, touts a “Four Cs” approach to fleet infrastructure services: Consulting, Construction, Charging and Connecting.

“We can provide the very best bus or truck for our customers, but if they don’t have a partner to show them how to operate it, charge it or take care of it in the long run, it likely won’t be a successful deployment,” said Navistar Director of Business Development Jason Gies. “This partnership ensures that IC Bus and International Truck customers have the infrastructure support they need to ultimately be successful in electric.”

“The total cost of ownership with electric vehicles promises to be less than conventional vehicles; however, that is only possible with well-designed charging infrastructure and a trusted partner,” said In-Charge CEO Cameron Funk. “Navistar has the right vision and In-Charge is pleased to provide their end-to-end charging solution.”

Source: Navistar

source https://chargedevs.com/newswire/in-charge-energy-to-provide-charging-infrastructure-for-navistars-ev-customers/

Accelerated electrode drying could reduce battery production cost

A new EPIC project coordinated by Karlsruhe Institute of Technology (KIT) is aimed at accelerating the drying of electrodes for lithium-ion batteries, increasing the energy efficiency of this process and reducing production cost. KIT says innovative electrode drying management can reduce the cost of battery production and improve environmental performance.

The quality of Li-ion battery cells depends on the electrode layers that store the battery’s energy. Both the anode and the cathode material are applied in a thin layer of water-based or solvent-based paste onto a conducting foil made of copper (anode) and aluminum (cathode). Researchers of KIT’s Thin Film Technology (TFT) group developed a coating process that allows electrodes to be produced in less time than with traditional methods.

“It is important to analyze the individual process steps together and to consider interactions,” said the project’s coordinator, Professor Wilhelm Schabel. Other partners include Professor Jürgen Fleischer from KIT’s wbk Institute of Production Science, as well as researchers from the Center for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW) and the Technical University of Braunschweig.

SEE ALSO: Maxwell’s “dry electrode” process could save Tesla big bucks on battery manufacturing

EPIC focuses on energy-efficient drying technologies and optimal moisture management for the materials used along the process chain, from drying to cell assembly. TFT studies conventional drying processes, high-power radiators and drying management in general. “Higher coating speeds are particularly attractive when drying time can be reduced and the expensive drying line does not have to be extended,” said TFT’s Dr. Philip Scharfer.

wbk studies drying directly in the cell stack prior to electrolyte filling, as well as adjustment of the required cell moisture without prior drying in the cell stack directly before electrolyte filling. wbk, in cooperation with researchers from the Technical University of Braunschweig, evaluates how the drying intensity and duration influence cell properties. ZSW will model the production of industry-scale batteries and the exposure to moisture under a controlled production atmosphere on a scale comparable to that of series production.

The different approaches to production will be evaluated by the project partners using suitable process-cost models, and they will make recommendations for transferring the process to the industrial scale. In addition to energy and resource efficiency and battery cell quality, they will also consider environmental compatibility. The latest findings in production technology will be incorporated directly in the Post Lithium Storage (POLiS) cluster of excellence, in which KIT will develop future batteries together with Ulm University and ZSW.

SEE ALSO: Fraunhofer’s dry coating process for electrodes could make cell production in Europe economical

Source: KIT

source https://chargedevs.com/newswire/accelerated-electrode-drying-could-reduce-battery-production-cost/