France has announced an auto industry bailout package worth some 8 billion euros ($8.8 billion), and it includes substantial support for electrification. The new funds are in addition to a 5-billion-euro loan guarantee being considered for struggling Renault, and the many millions already spent on temporary unemployment payments to auto workers.

According to Le Monde, the auto sector employs some 900,000 people in France, and the industry saw an 89% drop in sales in April.

Speaking at a factory owned by French automotive supplier Valeo, President Emmanuel Macron said he wants France to become the leading producer of clean cars in Europe. “Our country should embody this avant-garde. We need not only to save [the industry] but transform it.”

Last week, Minister of Economy and Finance Bruno Le Maire said, “We are ready to support the demand for vehicles, but it will be support for clean vehicles that emit less CO2, especially electric vehicles.”

Macron unveiled a plan with “three motors,” as Le Monde put it. The job of the first motor is to stimulate demand; the second is tasked with localizing production in France; and the third aims to boost the competitive advantage of French firms by investing in cutting-edge technology.

The purchase incentive for BEVs and FCVs will increase from 6,000 to 7,000 euros, as of June 1. For fleet buyers, (which accounted for over 50% of the French market in 2019), the bonus for buying a plug-in vehicle will rise from 3,000 to 5,000 euros. (EVs priced at over 45,000 euros will receive only a partial subsidy, and those priced at over 60,000 euros will receive none.)

A new bonus of 2,000 euros has been added for PHEVs that have an electric range over 50 km, and cost less than 50,000 euros.

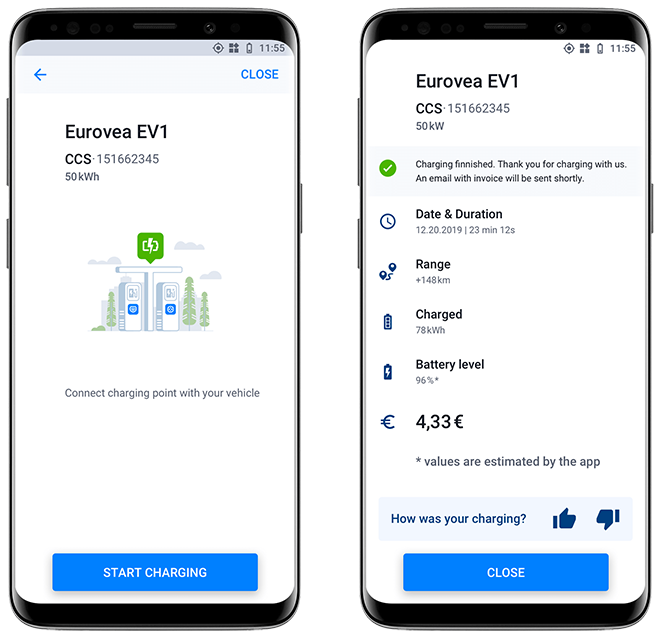

Investment in public charging will be accelerated to the tune of “tens of millions more euros.” Some 35,000-40,000 charging stations are to be deployed by the end of this year, and the goal is to have 100,000 in operation in 2021.

A prime à la conversion—what the Brits would call a scrappage program, or what we Yanks might call “cash for clunkers,” will offer incentives to drivers who upgrade to newer, less-polluting vehicles: 3,000 euros for an ICE vehicle, or 5,000 euros for a new EV or a conversion. The income qualification for the program will be loosened, so that approximately 75% of French households will be eligible for the subsidies (an increase from the existing figure of 50%).

The French government, which is a major stockholder in the country’s two largest automakers, has conditioned aid for Renault and PSA on promises that future EV production will be concentrated in France. The goal is to produce one million electrified vehicles (hybrids, EVs, PHEVs, FCVs) in France in 2025.

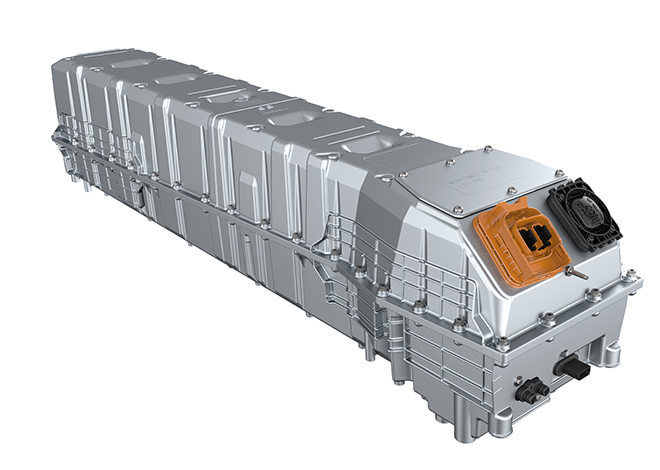

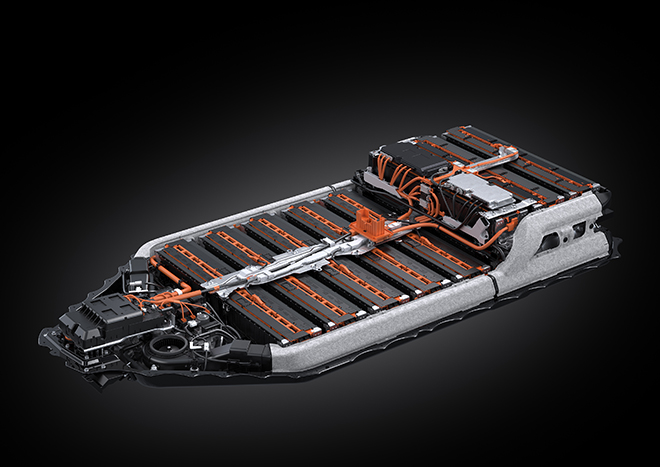

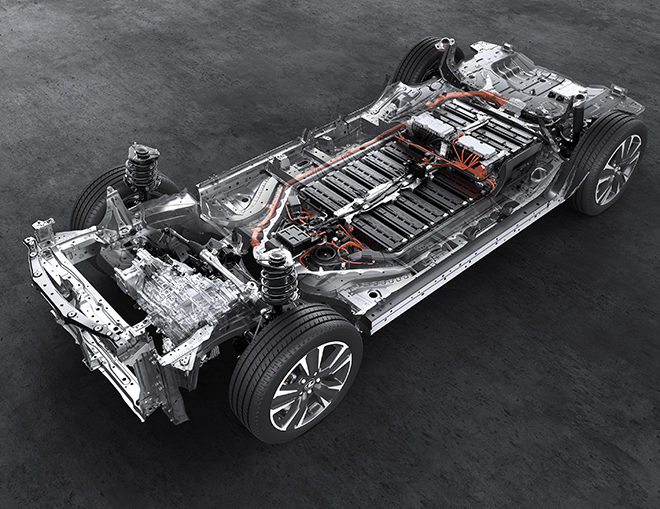

Renault is expected to build a new electric motor, to be used in EVs from the Renault-Nissan-Mitsubishi alliance, at its motor plant in Cléon, and aims to quadruple the number of EVs assembled in France in 2024. PSA is being asked to localize its electric powertrain production in France, and to quintuple its local plug-in production. The company has promised to build an electric version of the Peugeot 3008 at its plant in Sochaux, beginning in 2022 or 2023.

Both automakers will invest in a Franco-German partnership to produce batteries in Europe.

According to Le Monde, the new bailout package includes one billion euros to stimulate domestic supply, including 200 million to help smaller suppliers automate and modernize their production, and 150 million for research.

Sources: Le Monde, AP, Electrek

Image: Nicolas Raymond

source

https://chargedevs.com/newswire/frances-8-billion-euro-auto-industry-bailout-includes-support-for-evs/